SOFTENOL® 3829 to increase efficiency in aluminium processing

1. September 2022

The global balance in trade has been permanently disrupted by the corona pandemic, and Russia’s war against Ukraine is doing the rest. Due to the poor availability of gas, this has recently led to dramatically increasing energy costs, which is particularly problematic for the energy-consuming aluminium production.

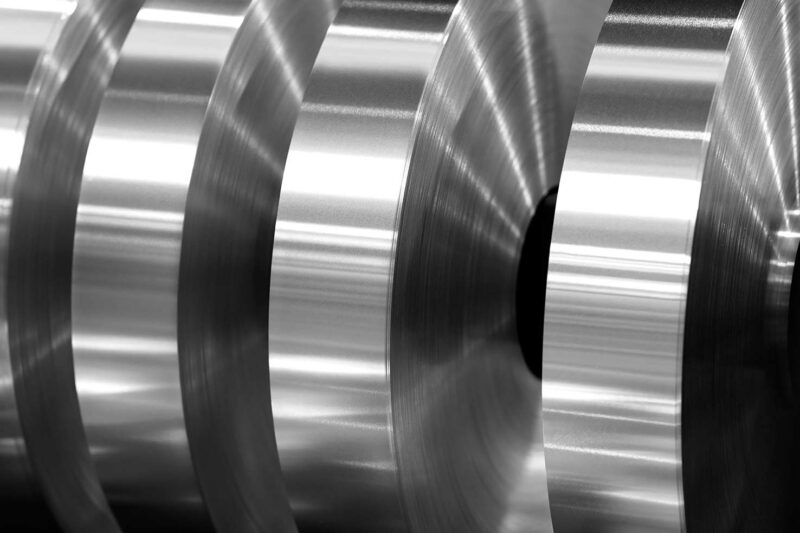

Our SOFTENOL® 3829 doesn’t help to reduce energy prices, but it does ensure that aluminium is processed more efficiently and therefore more cost-effectively in different ways. For example, for the production of menu trays for convenience meals (more about this in our article “Aluminium processing with food contact“). In combination with our SOFTENOL® 3803, the lubricant can even be used at lower temperatures in the production process.

Why is such a large amount of energy needed to produce aluminium?

After aluminium oxide is extracted from bauxite, an electrolytic reaction follows using cryolite to produce the aluminium. This electrolytic process requires enormous amounts of electrical energy. To put it more tangibly: The production of one ton of primary aluminium consumes on average 15 megawatt hours – as much as a two-person household in 5 years!

Regularly increasing electricity prices in Europe since the beginning of 2021, from formerly 50 €/MWh to sometimes up to 150-250 €/MWh, cost-efficient process management was necessary anyway. Due to the precarious situation in Eastern Europe, many countries are forced to look for alternative energy suppliers, which means that electricity prices will continue to rise.

Due to the close exchange with our customers, we are observing a significant decline in the production rate in Europe, which is leading to further increasing prices and thus affecting the aluminium processing companies further down the supply chain. The Technical Applications business unit at IOI Oleo GmbH develops tailor-made concepts for a wide variety of applications, which also ensure greater efficiency in aluminium production. By using our special ester SOFTENOL® 3829 as an aid for the deep drawing of rolled aluminium, costs in the aluminium processing industry can be reduced, taking various aspects into account:

Together with our customers, we regularly develop solutions to make production steps more efficient and reduce costs. As in this example by using SOFTENOL® 3829 with food contact or for alternative application methods, such as applying the lubricant with electrospray devices. Talk to us and let us work together to make this area of your production more efficient.

Dr. Andreas Wintzer

Dr. Andreas Wintzer is Technical Product Manager in the Technical Applications Business Unit at IOI Oleo GmbH. He studied Chemistry at TU Dortmund University with an emphasis on technical chemistry, particularly in the area of renewable raw materials. The extensive knowledge he acquired during his studies is the perfect basis for his work at IOI. Before joining IOI Oleo GmbH, Andreas completed a trainee programme at the European Space Agency in the Netherlands, then gained production experience as a technologist at Papierfabrik Hagen, which at the time belonged to the Stora Enso group. He enjoys sports, regularly rides to work by bike and preferably spends his leisure time with his family or friends.