Drug carriers à la carte from IOI – Precise individuality with WITEPSOL®

13. February 2022

According to a conservative estimate, approximately 1,000,000,000 (1 billion) individual patient doses are manufactured annually with our WITEPSOL® products for the application area of pain and fever management. This not only makes us proud, but also underlines our position as a global benchmark.

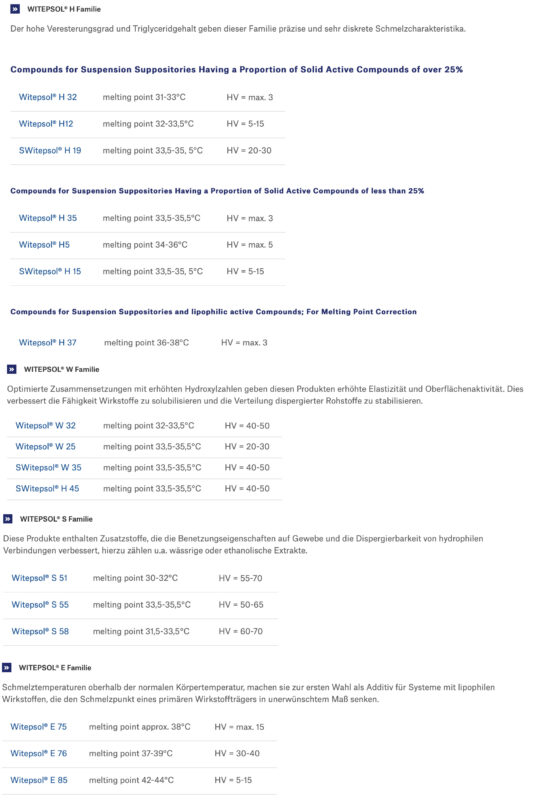

Contrary to the industrial trend towards streamlining and consolidating product portfolios, the Pharma business unit of IOI Oleo GmbH is sticking to the seventeen different active ingredient carriers within the four WITEPSOL® product families.

The individual products differ primarily in their chemical composition, melting points and behaviour, hydroxyl values and different additives used. Among others, anaesthetics, antidepressants, antiepileptics, vitamins, β-lactams, expectorants, hormones, steroids, laxatives, antifungals and opioids are being administered with this finely tuned toolbox of WITEPSOL® products.

In order to meet as many functional and regulatory customer needs as possible, we maintain this comprehensive spectrum of 17 finely accentuated excipients.

Melting Point:

As part of the selection of raw materials for a development project, the interaction of the ingredients in a formulation is examined and any changes in the melting point are considered. The melting point of a formulated API / carrier system largely determines the release profile. (More about release profiles in this post: Promising trends from the US market).

Hydroxyl Value:

The hydroxyl value determines the suitability for releasing specific APIs. It describes the ability of the drug carrier to stabilize the distribution of hydrophilic and / or suspended or dispersed ingredients in the matrix and to facilitate the absorption of less easily absorbable drugs.

Additives:

The addition of certain additives has shown that both the dispersibility of active ingredients and the wetting of mucous membranes, and thus absorption, are promoted.

In addition to the individual properties of the WITEPSOL® families, the products overall are characterized by the following properties:

More than a billion patient doses produced with our seventeen WITEPSOL® products underline the commitment of our customers and the commitment of IOI Oleo GmbH to patient health worldwide. At the same time, this figure makes it clear that we have the right solution for a wide variety of applications. Contact us and our local IOI Oleo GmbH representatives to find out what WITEPSOL® can do for your patients.

Robert Radsziwill

Robert is the Business Development Manager for Functional Excipients in the Pharma Division of IOI Oleo GmbH. Prior to this role he held technical and commercial roles focusing raw materials used in the pharmaceutical and medical device industry for 13 years. In each position he leveraged his diploma degree in Business Chemistry earned at Westfälische Wilhelms-University to drive interdisciplinary projects and work as interface between commercial and technical decision makers. Understanding technical, commercial and regulatory drivers from ideation to successful project-completion is key for him. In his free time he enjoys guitar heavy music as well as cooking for and with family and friends.