Detailed insights into the world of technical applications with scanning electron microscopy

5. June 2023

There is a world that remains hidden to most people – the fascinating world of surfaces at the microscopic level. At the “Technical Applications” business unit at IOI Oleo GmbH, we apply state-of-the-art technologies every day in order to offer our customers the best possible quality and innovation. Scanning electron microscopy (SEM) is one of these technologies that play a pivotal role in our day-to-day work.

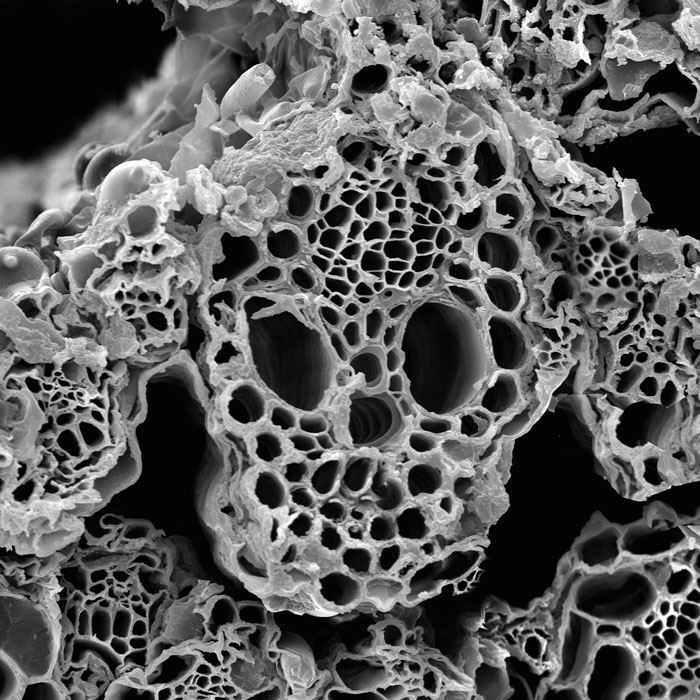

Using SEM, particularly the surface of samples can be examined with an electron beam, which makes it possible to view complex and fine structures in an impressive image quality. For us, that is crucially important; SEM enables us to look more precisely at our customers’ semi-finished and finished products and not only ensure and further improve the quality and functionality of our oleochemical specialties, but also provide decisive support for our customers in the optimisation of their processes.

Especially in the area of expandable polystyrene (EPS), SEM brings enormous advantages. EPS is used in a large variety of industries as an insulation or packaging material. Many customers all over the world rely on our oleochemical coating agents to guarantee the optimal processability and final performance of the product. With the aid of SEM, we are able to closely examine the surface of the EPS and, with that, the coating result, ensuring the quality of our work.

Lemongrass cross section under an SEM

SEM allows us to offer our customers even more service

We can examine specific products in higher magnification, identify potential errors on the surface and optimise accordingly. In this way, we ensure that every product that leaves our BU meets our high quality standards.

Did you know? With optional detectors, e.g. the EDX detector, we can even carry out an elemental analysis of samples. This helps us to determine the origin of certain contaminants, which is particularly useful in quality analyses.

Our work with scanning electron microscopy shows how technical progress, precision and passion for detail go hand in hand in our company. Our aim is to offer our customers even more technical service and quality through this advanced technology.

Dr. Andreas Wintzer

Dr. Andreas Wintzer is Technical Product Manager in the Technical Applications Business Unit at IOI Oleo GmbH. He studied Chemistry at TU Dortmund University with an emphasis on technical chemistry, particularly in the area of renewable raw materials. The extensive knowledge he acquired during his studies is the perfect basis for his work at IOI. Before joining IOI Oleo GmbH, Andreas completed a trainee programme at the European Space Agency in the Netherlands, then gained production experience as a technologist at Papierfabrik Hagen, which at the time belonged to the Stora Enso group. He enjoys sports, regularly rides to work by bike and preferably spends his leisure time with his family or friends.