DYNASAN® 118 – Your Formulation Challenges – Our Solutions

21. October 2021

In 1843 the Englishman William Brockedon (1787 – 1854) applied for a patent for the tablet and caused “one of the most tremendous upheavals that the pharmacists have ever experienced”1. Thereby active ingredients can be precisely dosed and are very stable, the taking is convenient, the production cheap and they are easy to transport. As a result, tablets occupy a special position today with a share of almost 50% among the drug forms.

However, pressing tablets regularly poses various challenges for galenical experts. For the compression of powders and granulates into tablets, auxiliaries are required that give the tablet mechanical and chemical stability and simplify the production process. In addition to bulking agents, binders and disintegrants, tabletting lubricants are of great importance. Typically, this category of functional adjuvant is of oleochemical origin. The materials support the powder flow and the compacting process of the tablet body, enable defect-free ejection from the tablet matrix and, depending on the dosage, can also modulate release profiles.

The Pharma business unit of IOI Oleo GmbH offers a variety of plant-based mono-, di- and triglycerides for a wide variety of dosage forms. Our DYNASAN® portfolio is particularly suitable for producing tablets. The products are lipid-based and can not only help to overcome the formulation hurdles, but also to simplify the production of the tablets.

The chemical origin, the raw materials and the production under GMP conditions give the DYNASAN® product range advantageous properties and an optimized purity profile. The high degree of esterification leads to negligible free OH functionality and results in an extremely inert auxiliary. DYNASAN® products are to be distinguished from the metal soaps, that are typically used as lubricants. The following difficulties occur regularly with metal salts from fatty acids 2:

Ibuprofen, acetylsalicylic acid, norfloxacin, glimepiride, cephalexin, indomethacin, ketoprofen, temazepam, glibenclamide, penicillin G, oxacillin, clopidogrelbesylate, erythromycin, captopril.

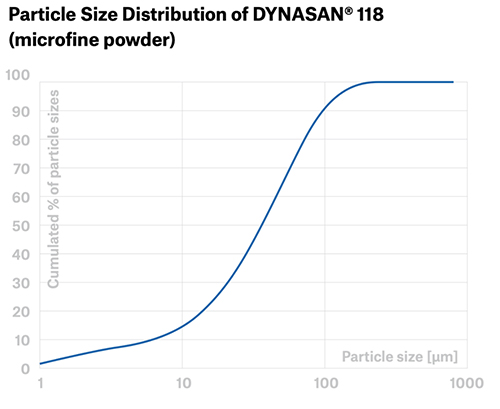

In our DYNASAN® product family, DYNASAN® 118 is the highlight, thanks to the USP-NF monograph „Glyceryl Tristearate“ . For galenic experts this is official proof that this product is suitable for the production of pharmaceuticals. Supplied as a microfine powder, it offers a number of benefits for the formulator 3,4.

We have put together further details for you in our brochure “Lipids for solid dosage forms”. We are at your disposal for further information or product samples.

[1. Wolf-Dieter Müller-Jahncke, Christoph Friedrich, Ulrich Meyer: Arzneimittelgeschichte. 2., überarb. und erw. Auflage. Wiss. Verl.-Ges, Stuttgart 2005, S. 31 ff]

[2. Lubricants in Pharmaceutical Solid Dosage Forms, Jinjiang Li and Yongmei Wu, Lubri- cants 2014, 2, 21-43 ]

[3. Lubricating properties of triacylgycerols related to the release of medicaments: M. Vitko- va; M. Chalabala; J. Rak, Faculty of Pharmacy, 832-32, Bratislava, Czecho-Slovakia]

[4. A. Stamm, Sci. Techn. Pharm. 9 (1), 471 – 478 (1980)]

Robert Radsziwill

Robert is the Business Development Manager for Functional Excipients in the Pharma Division of IOI Oleo GmbH. Prior to this role he held technical and commercial roles focusing raw materials used in the pharmaceutical and medical device industry for 13 years. In each position he leveraged his diploma degree in Business Chemistry earned at Westfälische Wilhelms-University to drive interdisciplinary projects and work as interface between commercial and technical decision makers. Understanding technical, commercial and regulatory drivers from ideation to successful project-completion is key for him. In his free time he enjoys guitar heavy music as well as cooking for and with family and friends.